Contact Us

|

||||

Paper

Press release

|

Kansai University and Murata Manufacturing Co., Ltd. Press Launch On September 21, Kansai University and Murata Manufacturing Co., Ltd. announced the development of a sensor device using high-transparency organic piezoelectric film at a press conference on Senriyama Campus. Professor Yoshiro Tajitsu, Faculty of Engineering Science, explained the mechanism of occurrence of piezoelectric phenomenon in the high-transparency organic piezoelectric film, and described its development method, following an explanation of the sensor device by Mr. Masamichi Ando, chief researcher at Murata Manufacturing Co., Ltd. The device will be exhibited at the CEATEC JAPAN 2011, cutting-edge IT & Electronics comprehensive exhibition, held in Makuhari Messe, Chiba, from October 4 to 8. Kansai University Press Release(Japanese Only) For details, please see Murata Manufacturing Co., Ltd. Website.

Professor Yoshiro Tajitsu, Faculty of Engineering Science |

|

Development of Sensor Device Using High- Transparency Organic Piezoelectric Film

Septemver21,2011

Murata Manufacturing ColLtd. President,Statutory Representative Director: Tsuneo Murata Overview Murata Manufacturing Co., Ltd. has developed a sensor device using high- transparency organic piezoelectric film. This film has the following characteristics: (1) high piezoelectric output constant*1; (2) high transparency (light beam transmittance of 98% or higher [according to the internal haze measurement]); and (3) free from pyroelectric effect*2. This film can also detect twisting motion, and therefore there is high expectation for its application to various human machine interfaces. Murata has newly developed devices that apply this piezoelectric film, such as a Leaf Grip Remote Controller that can control the TV using a bending and twisting motion and a "touch pressure pad," which is a touch panel that can detect pressure. Background As smartphones, tablet computers, and portable game devices become more widespread, there is a growing demand for a new human/machine interface. Conventional piezoelectric films are usually subject to a pyroelectric effect, which is a disadvantage because they cannot detect bending and twisting vibrations separately from changes in temperature. Murata has developed a high-transparency piezoelectric film free from pyroelectric effect through joint research with Kansai University and Mitsui Chemicals Inc. Applied device LeafGrip Remote Controller

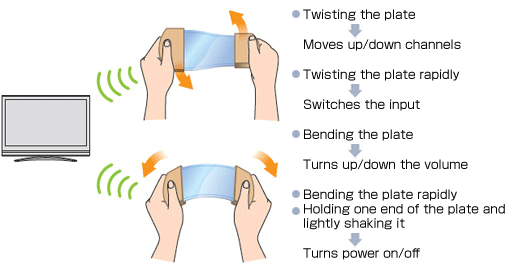

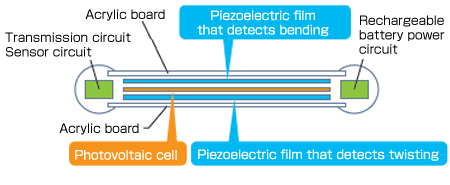

Leaf Grip Remote Controller using piezoelectric film (sample)

This remote control has a very new conceptual design that enables it to operate by bending and twisting of a plate made of piezoelectric films that can detect such motions. Furthermore, it uses pigments to discharge electrons when it receives light and is assembled with a photovoltaic cell that converts light into electricity to provide it with a battery-less feature. Example of use This remote control can operate a TV by bending or twisting of its plate.

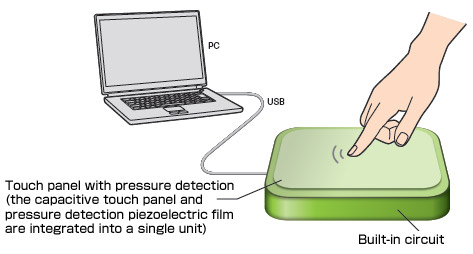

"touch pressure pad" --touch panel with pressure detection

Touch pressure pad using piezoelectric film (sample)

Since this piezoelectric film is not subject to the pyroelectric effect, simply touching it with a finger does not generate voltage. As a result, the piezoelectric film is capable of high-precision detection. Furthermore, it can detect finger movement in the left/right and up/down directions as well as pressing force (how strongly it is pressed). Example of use Pressing the touch panel enlarges the data on the touch panel. This feature can be used to enlarge data quickly by pressing the panel with a strong force, and enlarge it slowly by pressing the panel with a weaker force.

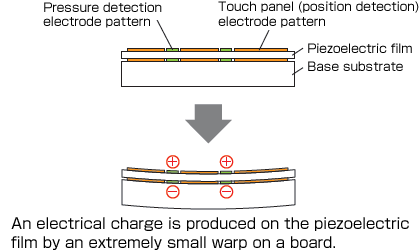

Mechanism

We will exhibit these devices and provide demonstrations using these devices at CEATEC JAPAN 2011 to be held in Makuhari Messe in Chiba Prefecture from October 4th to 8th. Terminology *1 Piezoelectric output A value obtained by dividing the piezoelectric constant: strain constant by the dielectric constant. This value is used as an indicator of sensor sensitivity. When this constant is higher, the sensor sensitivity is also higher. *2 Pyroelectric effect: A change in the temperature changes the surface electrical charge of dielectrics. The temperature change can be detected using a pyroelectric device. Applications Displacement sensor (sensor used for detecting bending and twisting) Touch panel Electrical Performance Piezoelectric output constant (g31 180 x 10-3Vm/N conversion) : Dielectric constant: 2.5 Sample Shipment Displacement Sample shipment planned for spring 2012 sensor: Note: The timing for commercial application of photovoltaic cells is not yet defined. Touch panel: Sample shipment planned for autumn 2012 Patenting Information Patents pending for approximately 30 items related to materials and applied devices. |

|

NEWS RELEASE

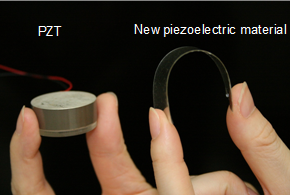

Teijin & Kansai University Develop New Piezoelectric Material

First Binary-blended Polylactic Acid Multilayer Film with Unprecedented Piezoelectric Effect Osaka / Tokyo, Japan, September 6, 2012 --- Teijin Limited and Kansai University announced today that Teijin’s New Films Development Section and Professor Yoshiro Tajitsu, Faculty of Engineering Science, Kansai University, have developed a flexible, transparent piezoelectric material that demonstrates unprecedented piezoelectric effects. The piezoelectric effect is the generation of electric power in proportion to the strain produced when pressure is applied to certain materials, used in impact/vibration sensors. The inverse piezoelectric effect is the distortion caused by applying electric power, used in audio speakers, ultrasonic transducers and other actuators that convert electric energy into motion. The new material is made with a simple manufacturing process that alternately laminates two types of polylactic acid (PLA) films: poly-L-lactic acid (PLLA) and optical isomer poly-D-lactic acid (PDLA). As the world’s first binary-blended PLA multilayer film with piezoelectric performance that surpasses that of lead zirconate titanate (PZT), a conventional and widely used piezoelectric material, the new material, which is also environmentally conscious, is expected to pave the way for larger and more lightweight products that have been difficult to achieve.

Going forward, the team will continue joint research and development aimed at achieving a wide range of applications, such as sensors that can detect pressure, vibration and impact, as well as ultrasonic motors, ultrasonic transducers for medical care and actuators used in devices such as speakers. The new material can be manufactured with a simple and practical coextrusion method. By alternately inserting positive and negative electrodes between PLLA and PDLA films, which exhibit piezoelectricity motion in opposite directions when exposed to electric fields of the same direction, the piezoelectricity motion can be aligned in the same direction. Piezoelectric performance can be controlled by varying the number of layers, enabling customized designs to suit specific needs. Research by Professor Tajitsu revealed that when PLA exceeds a certain level of purity, piezoelectricity improves dramatically. By using high-purity PLLA and PLDA achieved with Teijin’s advanced PLA refining technology, the new multilayer film demonstrates superior piezoelectric performance. In 2006, Teijin developed Biofront, a highly heat-resistant bioplastic with a melting point of over 210°C, by forming a stereocomplex structure from L-lactic acid and D-lactic acid. Work on new applications is ongoing. Background Until now, inorganic materials have been used widely as piezoelectric materials, particularly PZT because of its high piezoelectric performance. PZT is a designated hazardous substance that contains lead, but because there is no other material that can be used as a substitute, PZT is exempt from the EU directive that restricts the use of certain hazardous substances in electrical and electronic equipment. Also, because PZT is a ceramic material, it lacks flexibility and is difficult to increase its size or reduce its weight. Polyvinylidene fluoride (PVDF) is an organic-based piezoelectric material, but its action is weak due to an inverse piezoelectric effect. In addition, because PVDF generates an electric charge when exposed to heat, it is difficult to use PVDF as a material for electrical and electronic equipment, so applications are limited to sensors and such. To achieve piezoelectric effects, a direct-current, high electric field must be applied when manufacturing PVDF and PZT, so the process has a high energy load. In contrast, it is widely known that PLA films orient when drawn, so piezoelectric effects can be generated in a specific direction. However, this effect is short lived and a practical application level has not been reached. It is also known that when a drawn PLA film is laminated, the piezoelectric effect increases. However, because deformation (shearing) into a rhomboid shape occurs due to the piezoelectric effect, it is difficult to laminate the film into multilayers to generate a piezoelectric effect with a uniform direction. As a result, it has been difficult to adjust the number of layers, and continuous production of a multilayer film consisting of single-type PLA films has been a challenge. About the Teijin Group Teijin (TSE 3401) is a technology-driven global group offering advanced solutions in the areas of sustainable transportation, information and electronics, safety and protection, environment and energy, and healthcare. Its main fields of operation are high-performance fibers such as aramid, carbon fibers & composites, healthcare, films, resin & plastic processing, polyester fibers, products converting and IT. The group has some 150 companies and around 17,000 employees spread out over 20 countries worldwide. It posted consolidated sales of JPY 854.4 billion (USD 10.7 billion) and total assets of JPY 762.1 billion (USD 9.5billion) in the fiscal year ending March 31, 2012. Please visit www.teijin.co.jp/english. About Kansai University In 2012, Kansai University celebrated the 126th anniversary of its founding as one of the leading comprehensive universities in Japan. Kansai University is a prestigious private university with 13 undergraduate and 12 graduate programs along with 3 professional graduate schools. There are over 30,000 students enrolled at the university including more than 700 international students. Kansai University has graduated 400,000 students and they are participating actively in many fields around the world. Kansai University aims to nurture top runners who can make a contribution to society. We strive to present the world with new ideas and innovations, and are always dynamic and on the go. |

|

NEWS RELEASE

Kansai Univ., Teijin Develop World’s First Piezoelectric Fabrics for Wearable Devices

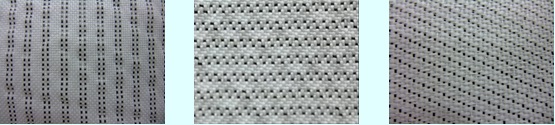

Tokyo, Japan, January 13, 2015 --- Kansai University and Teijin Limited announced today that Professor Yoshiro Tajitsu, Faculty of Engineering Science, Kansai University, and Teijin have developed the world’s first polylactic acid (PLA) fiber- and carbon-fiber-based piezoelectric fabrics. The new piezoelectric fabrics combine Teijin’s polymer and textile technologies-a Teijin growth strategy to integrate key existing materials and businesses-with Prof. Tajitsu’s world-leading knowledge of piezoelectric materials. Development was supervised by Prof.Tajitsu at Kansai University, with technological cooperation provided by the Industrial Technology Center of Fukui Prefecture.

New piezoelectric fabrics (from left: plain weave, twill weave and satin weave) The fabrics comprise a piezoelectric polyctric poly-L-lactic acid (PLLA) and carbon fiber electrode. Plain, twill and satin weave versions were produced for different applications: plain weave detects bending, satin weave detects twisting, and twill weave detects shear and three-dimensional motion, as well as bending and twisting. The sensing function, which can detect arbitrary displacement or directional changes, incorporates Teijin’s weaving and knitting technologies. The function allows fabric to be applied to the actuator or sensor to detect complicated movements, even three-dimentional movements. Kansai University and Teijin will introduce the new piezoelectric fabric (booth No. 18-11, East Hall) at The 1st Wearable Expo, the world’s largest wearable devices and products exhibition, which will be held at the Tokyo International Exhibition Hall (Tokyo Big Sight) in Japan from January 14 to 16. Kansai University and Teijin will continue working on ideal weaves and knits for fabric applications that enable elaborate human actions to be monitored simply via clothing worn by people. Such applications are expected to contribute to the evolution of the Internet of Things (IoT) in fields ranging from elderly care to surgery, artisanal techniques to space exploration, and many others. Piezoelectricity is the ability of certain dielectric materials to generate an electric charge in response to mechanical stress. It also has the opposite effect - the application of electric voltage produces mechanical strain in the materials. Both of these effects can be measured, making piezoelectric materials effective for both sensors and actuators. Lead zirconate titanate (PZT) has practical piezoelectric applications in industry, but as a ceramic material it lacks transparency and flexibility. In addition, because PZT contains lead, applications are being increasingly limited by the EU directive that restricts the use of certain hazardous substances in electrical and electronic equipment. Polyvinylidene fluoride (PVDF) is a well-known piezoelectric polymer. However, it is limited to use in sensors and such , and it is not suited to industrial-level manufacturing because it requires poling treatment and exhibits pyroelectricity. Poling treatment, which involves applying high DC voltage to a material, is a required process for achieving piezoelectricity. Pyroelectricity is the ability of certain materials to generate a voltage and charge following a change in temperature. The existence of pyroelectricity is very important factor in human-machine interface (HMI) applications because if a piezoelectric sensor material has pyroelectricity, then it can immediately detect heat from a finger. In 2012, Kansai University and Teijin developed a flexible, transparent piezoelectric film by alternately laminating PLLA and optical isomer poly-D-lactic acid (PDLA). The all-new wearable piezoelectric fabric announced today is the newest application of this technology.

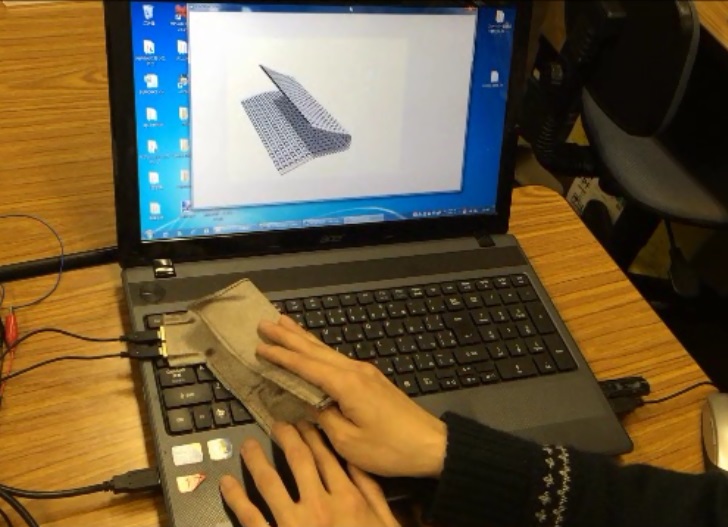

CAD data can immediately reflect the folding of a piezoelectric fabric. About Kansai University In 2015, Kansai University celebrates the 129th anniversary of its founding as one of the leading comprehensive universities in Japan. Kansai University is a prestigious private university with 13 undergraduate and 12 graduate programs along with 3 professional graduate schools. There are over 30,000 students enrolled at the university including more than 700 international students. Kansai University has graduated 400,000 students and they are participating actively in many fields around the world. Kansai University aims to nurture top runners who can make a contribution to society. We strive to present the world with new ideas and innovations, and are always dynamic and on the go. About the Teijin Group Teijin (TSE: 3401) is a technology-driven global group offering advanced solutions in the areas of sustainable transportation, information and electronics, safety and protection, environment and energy, and healthcare. Its main fields of operation are high-performance fibers such as aramid, carbon fibers & composites, healthcare, films, resin & plastic processing, polyester fibers, products converting and IT. The group has some 150 companies and around 16,000 employees spread out over 20 countries worldwide. It posted consolidated sales of JPY784.4 billion (USD 7.7 billion) and total assets of JPY 768.4 billion (USD 7.5 billion) in the fiscal year ending March 31, 2014. Please visit www.teijin.com. |

Web News

|

No.

|

Contents

|

Broadcast

|

Date

|

|

1

|

China Plastic & Rubber Journal

|

13 September 2012

|

|

|

2

|

BioBased Digest (US)

|

11 September 2012

|

|

|

3

|

Medical Plastics News (UK)

|

10 September 2012

|

|

|

4

|

A to Z of Materials (Australia)

|

7 September 2012

|

|

|

5

|

BioSpace(US)

|

13 January 2015

|

|

|

6

|

IHS Chemical Week(US)

|

13 January 2015

|

|

|

7

|

just-style(UK)

|

14 January 2015

|

|

|

8

|

fibre2fashion(India)

|

15 January 2015

|

|

|

9

|

Innovation in Textiles(UK)

|

15 January 2015

|

|

|

10

|

Advanced Textiles Source(US)

|

6 March 2015

|

TV News

|

No.

|

Contents

|

Broadcast

|

Date

|

|

1

|

New remote puts a twist in channel surfing

|

CBS News(USA)

|

5 October 2011 0:40

|

|

2

|

Health tech and clever controls at Ceatec

|

BBC News(UK)

|

14 October 2011 15:34

|

|

3

|

Tailoring for the Tech Era

|

NHK World News(JP)

|

14 January 2015

|